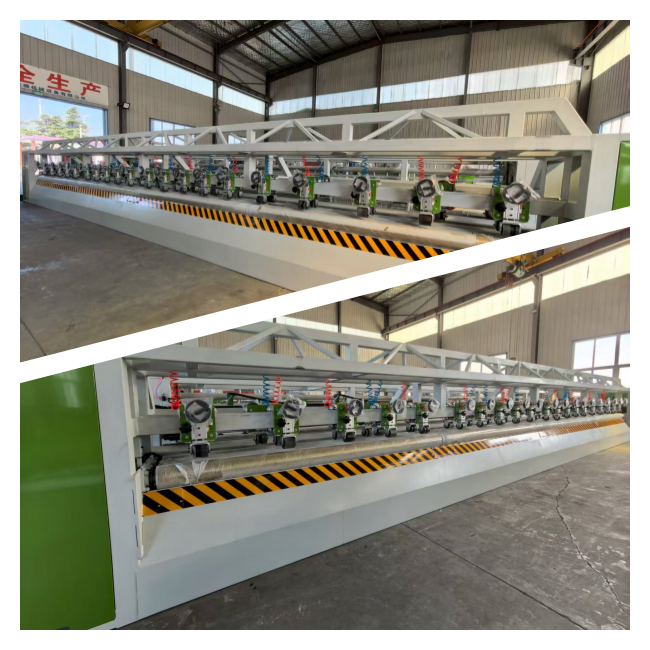

fully automatic machine

6m Auto Welding Punching Cutting Machine

Technical Specifications for Standard Line

| Parameter | Specification |

|---|---|

| Max. Material Width | 2-4 meters |

| Production Speed | 10-25 meters/minute |

| Min. Seam Width | 15-25 mm |

| Power Requirements | 380V, 50-100A three-phase |

| Floor Space | 15-30 meters length × 4-6 meters width |

| Staff Required | 1-2 operators for monitoring |

Key Principles: How It Works

The core principle is thermal butt welding (also known as hot plate welding). The process typically involves four main steps:

Facing: The two hose ends are trimmed simultaneously with a cutting tool to ensure they are perfectly square and clean.

Heating: The squared ends are pressed against a heated platen (Teflon-coated or aluminum) at a specific temperature until the material becomes molten.

Retraction: The heating platen is removed.

Joining (Fusion): The two molten ends are quickly pressed together with a controlled force and held steady under pressure as they cool and solidify.

Categories

Products

Contact Us

Contact: Tarpaulin Welding Machine QINGDAO XINRUIDE MACHINERY EQUIPMENT CO.,LTD

Phone: +86 13805420368

Tel: +86-0532-88265055

E-mail: wangrui@tarpweld.com

Add: Lianggezhuang Village, jiaobei office, jiaozhou city, qingdao city, shandong province.